FRP process pipe

Weight

- 产品描述

-

- Commodity name: FRP process pipe

FRP process pipes are produced using a reciprocating fiber winding process, using vinyl polyester resin as the matrix and alkali-free glass fiber yarn and its products as reinforcing materials. No fillers are added. According to the pre-designed line shape and thickness, the fiberglass pipe is processed by a microcomputer.

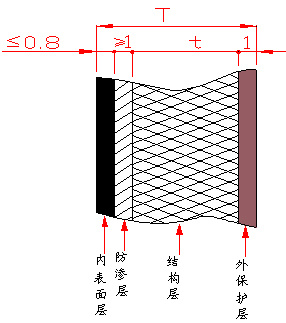

FRP process pipes are produced using a reciprocating fiber winding process, using vinyl polyester resin as the matrix and alkali-free glass fiber yarn and its products as reinforcing materials. No fillers are added. According to the pre-designed line shape and thickness, the fiberglass pipe is processed by a microcomputer. Controls wrapping wire production. Fiberglass process pipe wall structure diagram:

1. Performance characteristics

1. Excellent water resistance and corrosion resistance: Scientific and reasonable resin selection and process layup design ensure that the pipeline has excellent waterproof, anti-seepage and chemical corrosion resistance.

2. Good mechanical properties and high specific strength: the tensile strength of FRP pipes is ≥320Mpa; impact resistance: the weight of a dropped weight of 1.5kg will not be damaged at an impact height of 1.6m. The specific strength is 3 times that of steel pipes and 10 times that of ductile iron pipes. , 25 times that of concrete pipes.

3. Excellent temperature resistance: The long-term use temperature of FRP pipes is generally -40°C to 70°C. If high-temperature-resistant resin is used, FRP pipes can operate under high temperature conditions of 120°C for a long time and maintain good mechanical properties.

4. Small specific gravity, light weight, easy to transport and install: the specific gravity is only 1/4 to 1/5 of steel and cast iron pipes, and 2/3 of concrete; the weight is about 1/4 of ductile iron pipes of the same specification and length. , 1/10 of concrete pipe. Therefore, it is easy to load and unload, easy to transport and install.

5. Flexible interface, high security, multiple interface types:

◆ “O” type sealing ring socket connection (including lock key)

◆ Socket cementing

◆Threaded connection

◆Flange connection

◆ Butt wrapping

6. Low maintenance costs: FRP pipes have excellent corrosion resistance, wear resistance, frost resistance and anti-fouling properties, so there is no need for special anti-rust, anti-fouling, insulation, heat preservation and other measures and maintenance. There is no need for cathodic protection for underground pipes, which can save engineering maintenance costs.

7. Long service life, safe and reliable: The designed service life of FRP pipes is based on 50 years, which is twice that of steel pipes and concrete pipes; for highly corrosive media, its service life is much higher than that of steel pipes.

8. Flexible design and strong product adaptability: Products with various specifications, pressure levels, stiffness levels or other special properties can be manufactured according to the user's various special usage requirements by changing the design, with a wide range of applications.

2. Implementation standards

JC/T552-2011 "Filament wound reinforced thermosetting resin pressure pipe"

HG/T4372-2012 "Composite pipes and fittings for chemical industry"

HG/T21633-1991 "Fiberglass Pipes and Fittings"

ASTM D3262-2006 《Specification for Fiberglass (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer Pipe》

Key words:- 玻璃钢工艺管

Previous Page

Related Products

online message

WeChat Public Number

Nanjing Xinhe Composites Co.,Ltd.

Address: KAIPING RD ,DONGPING HI-TECH DEVELOPMENT ZONE,NANJING,JIANGSU,CHINA,211212

Fax: 025-57493228

Tel: 025-57492608

Email: admin@nnfrp.com

copyright©2023 Nanjing Xinhe Composites Co.,Ltd.

Website Construction: www.300.cn nanjing |SEO Tags