Ship and offshore engineering system pipelines

Weight

- 产品描述

-

- Commodity name: Ship and offshore engineering system pipelines

Ship and offshore engineering system pipelines, also known as reinforced epoxy resin fiberglass system pipelines, use high-quality epoxy resin systems and glass fiber reinforced materials. The microcomputer-controlled layup program is wound onto the pipe or pipe fitting mold, and is finally heated and solidified. Form epoxy fiberglass pipe or pipe fitting products with stable performance.

Ship and offshore engineering system pipelines, also known as reinforced epoxy resin fiberglass system pipelines, use high-quality epoxy resin systems and glass fiber reinforced materials. The microcomputer-controlled layup program is wound onto the pipe or pipe fitting mold, and is finally heated and solidified. Form epoxy fiberglass pipe or pipe fitting products with stable performance.

1. Product features:

1. Corrosion resistance and long service life: According to the corrosive environment of seawater, by selecting the appropriate resin matrix and curing system, almost all corrosion problems can be easily solved;

2. Light weight, easy to install and transport;

3. Small friction coefficient, no scaling, and excellent hydraulic characteristics;

4. High specific strength and high pressure resistance;

5. The installation joint has good sealing performance: it adopts tapered socket bonding connection, which is fast, convenient and reliable;

6. Low operating cost and low maintenance cost: The smooth inner wall can reduce the accumulation of paraffin and scale;

7. Low surface friction increases the flow rate of fluid;

8. Good electrical and magnetic insulation properties;

9. Not restricted by geographical environment, thermal conductivity and static electricity;

10. Protect the environment: low energy consumption during production and use.

2. Dimensions: 1.5 inches to 40 inches (DN40mm to DN1000mm), single length 30 feet (9m) or 40 feet (12m);

3. Pressure level: up to 725PSI/5.0MPa;

4. Working temperature: maximum 120℃;

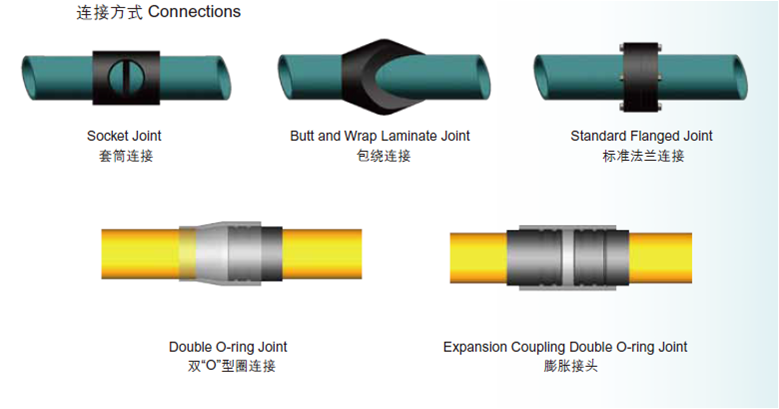

5. Connection method: double O-ring socket, glue joint, flange, sleeve and other joints;

6. Application scope: ballast, bilge, fuel, cleaning, ventilation, cooling, fire protection and other system pipelines;

7. Implementation standards:

IMO A.753(18) Guidelines for the Use of Plastic Pipes on Ships

ISO 14692 "Petroleum and natural gas industries —Glass-reinforced plastics (GRP) piping"

UKOOA-1994 "Specification and recommended practice for the use of GRP piping offshore"

ASTM F1173 "Standard Specification for Thermosetting Resin Fiberglass Pipe Systems to Be Used for Marine Applications"

ASTM D2996 "Standard Specification for Filament-Wound "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) pipe"

ASTM D2992 Standard Practice for Obtaining Hydrostatic or Pressure Design Basis for “Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin) pipe and fittings 》

ASTM D1599 "Standard Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe. Tubing, and Fittings"

API 15LR "Specification For Low Pressure Fiberglass line Pipe and Fittings"

Key words:

Key words:- 船舶与海洋工程系统管线

Previous Page

Next Page

Related Products

online message

WeChat Public Number

Nanjing Xinhe Composites Co.,Ltd.

Address: KAIPING RD ,DONGPING HI-TECH DEVELOPMENT ZONE,NANJING,JIANGSU,CHINA,211212

Fax: 025-57493228

Tel: 025-57492608

Email: admin@nnfrp.com

copyright©2023 Nanjing Xinhe Composites Co.,Ltd.

Website Construction: www.300.cn nanjing |SEO Tags