Fire-resistant fire protection system pipelines

Weight

- 产品描述

-

- Commodity name: Fire-resistant fire protection system pipelines

The fire-resistant fire protection system pipeline is a new product independently developed based on the high-pressure epoxy fiberglass pipes used in oil fields and combined with the fire protection and flame retardant requirements of the fire protection system. The system pipeline uses bisphenol A type epoxy resin and imported curing agent as the base material, and has high High-strength alkali-free glass fiber is a reinforcing material and other auxiliary materials, which are wound and formed through a special process.

The fire-resistant fire protection system pipeline is a new product independently developed based on the high-pressure epoxy fiberglass pipes used in oil fields and combined with the fire protection and flame retardant requirements of the fire protection system. The system pipeline uses bisphenol A type epoxy resin and imported curing agent as the base material, and has high High-strength alkali-free glass fiber is a reinforcing material and other auxiliary materials, which are wound and formed through a special process.

1. Product features: high pressure resistance, anti-corrosion, long service life; light weight, easy to install and transport; small friction coefficient, no scaling, excellent hydraulic properties; meets extreme flame retardant requirements such as pool fires and jet fires; anti-static.

1. The inner lining and outer protective layer of pipe fittings are rich in resin, have excellent corrosion resistance, are durable, and have a service life of not less than 30 years.

2. By optimizing the curing system and adding a fireproof isolation layer to the outer layer, the system pipeline has reached the flame retardant requirements of IMOA.753 (18) level three fire resistance and higher fire resistance levels such as impact fire, furnace fire, and jet fire. .

3. The layering process of conductive fibers is added during molding, which not only ensures the conductive performance, but also improves performance indicators such as strength.

4. It is easy, fast and easy to install and maintain; due to its light weight, it is easy to carry, which reduces the lifting cost; there are many connection methods, and the joint method can be selected flexibly according to the specific construction conditions. The installation is simple and fast, and the installation cost is low.

5. It has excellent hydraulic properties, has a smooth inner surface, small friction coefficient, good hydraulic properties, and the inner wall is wear-resistant.

6. Flexible design and strong product adaptability. Exclusive design and production can be carried out according to various special usage requirements of users.

2. Dimensions: 1.5 inches to 40 inches (DN40mm to DN1000mm), single length 30 feet (9m) or 40 feet (12m);

3. Pressure level: up to 725PSI/5.0MPa;

4. Working temperature: maximum 120℃;

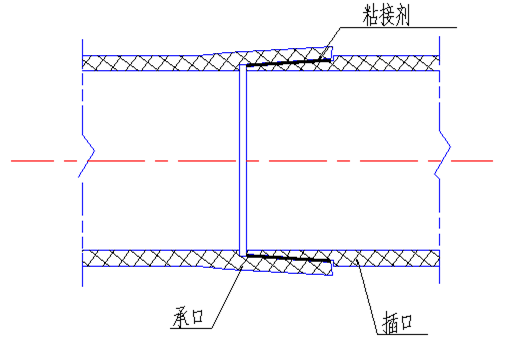

5. Connection method: Adhesive Bonded Joint, Bell/Spigot Double O-RING Joint;

6. Application scope: natural gas LNG, petrochemical industry, ships and offshore platform fire water supply pipelines;

7. Implementation standards:

IMO A.753(18) "Guidelines for the Use of Plastic Pipes on Ships"

IMO A.653(16) "Recommendation on Improved Fire Test Procedures for Surface Flammability of Bulkhead, ceiling and Deck Finish Materials"

OTI 95634 "Jet Fire Resistance Test Of Passive Fire Protection Materials" (Health And Safety Executive (UK), Offshore Technology Report, 1996)

8. Schematic diagram of socket bonding connection:

Key words:

Key words:- 耐火消防系统管线

Previous Page

Related Products

online message

WeChat Public Number

Nanjing Xinhe Composites Co.,Ltd.

Address: KAIPING RD ,DONGPING HI-TECH DEVELOPMENT ZONE,NANJING,JIANGSU,CHINA,211212

Fax: 025-57493228

Tel: 025-57492608

Email: admin@nnfrp.com

copyright©2023 Nanjing Xinhe Composites Co.,Ltd.

Website Construction: www.300.cn nanjing |SEO Tags